Valeo expansion, another joint milestone: new production facility in Veszprém handed over

- September 24, 2025

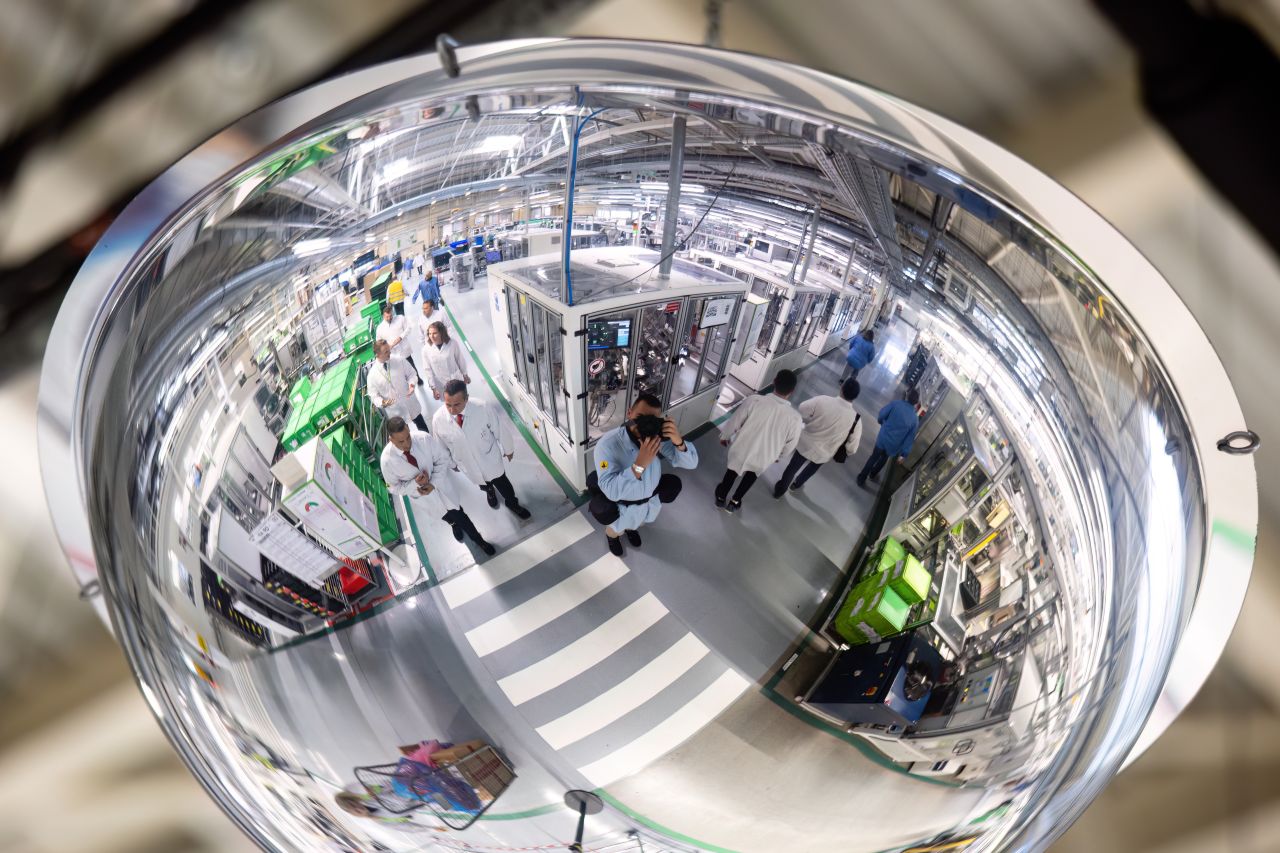

A few days ago, Valeo Auto-Electric Hungary Kft.’s new production facility in Veszprém was officially handed over. As part of the approximately 1,640 m² expansion, a 1,340 m² ISO7-rated production area (commonly referred to as a clean room), a small laboratory, and associated service rooms were built.

The new cleanroom not only enables the expansion of technological and manufacturing capacity, but also contributes to the broadening of the company’s portfolio. As a result, the latest 6th-generation driver assistance and parking camera systems will be manufactured here. The new production facility is one of the largest clean rooms of its kind in Europe, making it a significant milestone in domestic industrial development.

In the project, BuildEXT performed project management and technical supervision tasks, while BIM tools were used to support design and implementation. This methodology ensured accurate monitoring of deadlines and costs, coordinated communication, and the fulfillment of high quality expectations. During the implementation, we used the Dalux system, which we continuously adapted to the needs of the contractor and the investor during construction.

Our cooperation with the investor is not new: a few years ago, we also performed project management tasks for another similar expansion. At that time, a 1,200 m² clean room-certified production area was created in another part of the existing warehouse building.

The newly completed expansion is a further development of this successful collaboration. It clearly demonstrates how digitized project management can become one of the most important tools supporting developments in the manufacturing industry and how it can become one of the cornerstones of future construction projects.

Photo credit: Valeo’s official Linkedin profile